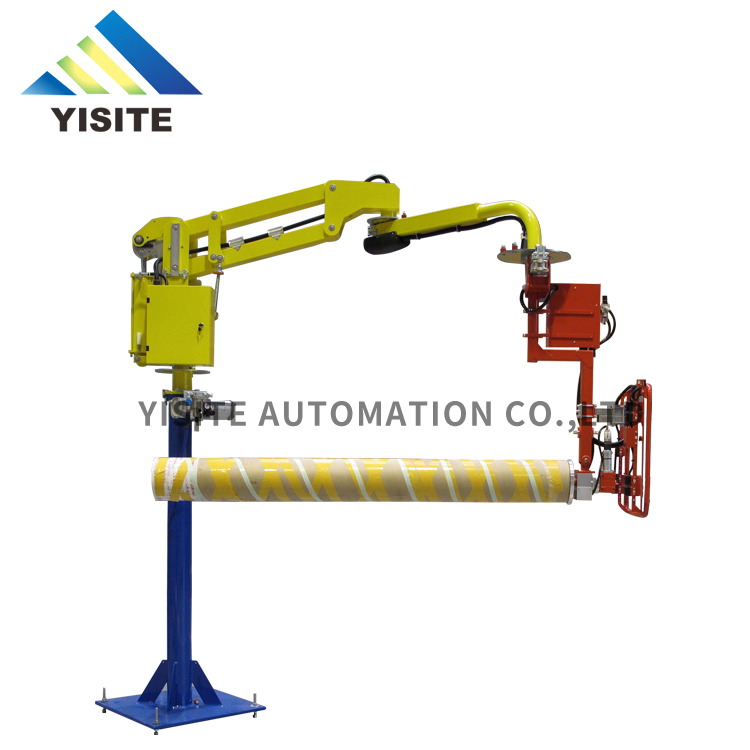

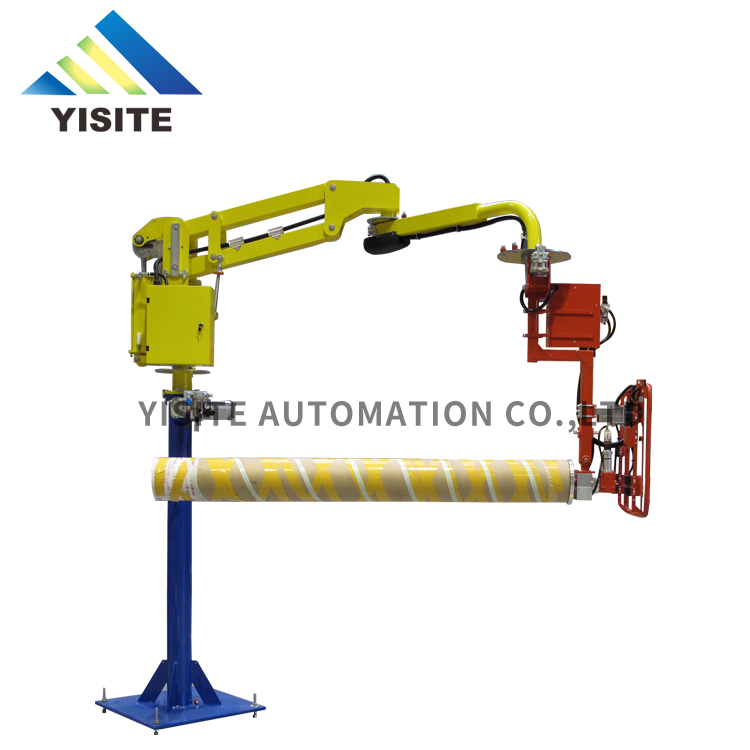

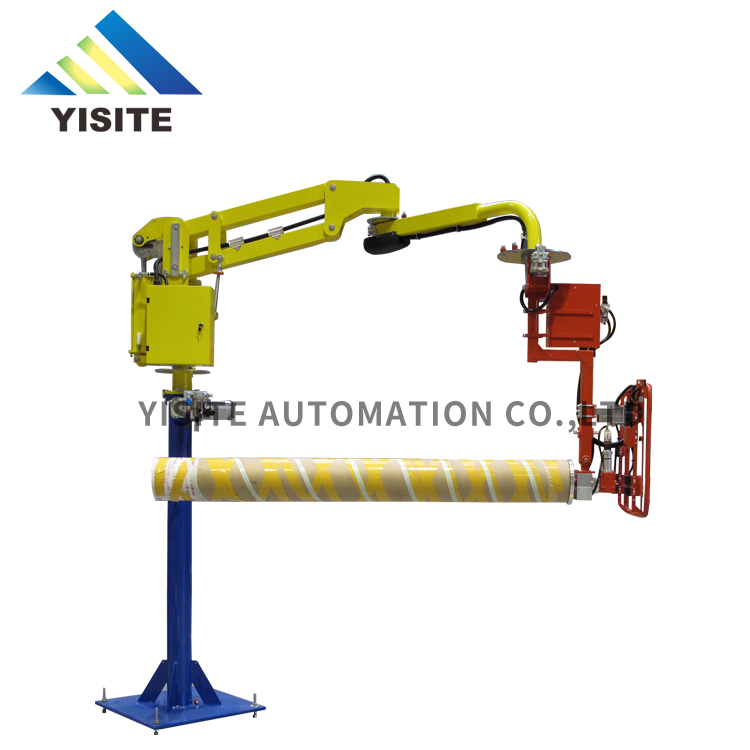

Pneumatic manipulator, also known as manipulator, balance crane, balance booster, manual load transfer machine (the above statement is not professional but is popular in China), is a novel, used for material handling and installation and labor saving operation of power equipment.

roll materials handling manipulator applies the balance principle of force, so that the operator can push and pull the heavy object accordingly, which can balance the moving positioning in space.The heavy object forms a floating state when lifting or decreasing, and non-operation force is guaranteed by the gas road (the processing process and design cost control, the operation force is less than 3kg as the judgment standard) the operation force is affected by the work-piece weight of the working piece.Without skilled operation, the operator can push and pull the heavy object by hand and put the weight properly in any position in the space.

about us

We are a professional customized automation equipment manufacturer. Our products include depalletizer, pick and place packing machine, palletizer, robot integration application, loading and unloading manipulators, carton forming,carton sealing,pallet dispensper,wrapping machine and other automation solutions for back-end packaging production line.

Our factory area is about 3,500 square meters. The core technical team has an average of 5-10 years of experience in mechanical automation, including 2 mechanical design engineers. 1 programming engineer, 8 assembly workers, 4 after-sales debugging person, and other 10 workers

Our principle is “customer first, quality first, reputation first”, we always help our customers “increase production capacity, reduce costs, and improve quality” we strive to become a top supplier in the machinery automation industry.