Products

automobile fuel tank handling manipulator

Product Features

1. High stability and simple operation.With full pneumatic control, only one control switch.

2. High efficiency and short handling cycle.After handling begins, the operator can control the movement of the piece in space with less force,And can stop at any position, the handling process is easy, fast and coherent.

3. High safety performance, and set up a gas break protection device.When the gas source pressure suddenly disappears, the artifact will remain in the original position without falling immediately.

4. The main components are all internationally famous brand products, with quality guaranteed.

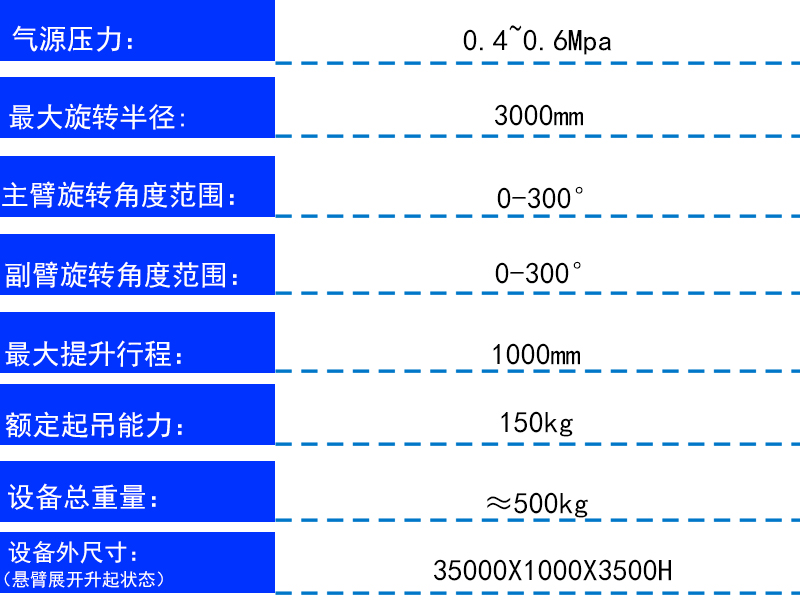

performance parameter

1、Air source pressure:0.4~0.6Mpa

2、Rotation radius:2000mm

3、Main arm rotation:0-300°

4、Auxiliary arm rotation:0-300°

5、Lifting stroke:600mm

6、Lifting range: 700mm-1250mm

7、Working pressure: ≥0.5Mpa

8、Lifting load capacity:70kg

9、Machine weight:≈400kg

10、Machine size:32600x 1300x3200H

11、Product size:L2200/1800xW1300/500xT10/5mm

Equipment function configuration

1. The main gas source of the equipment is equipped with a gas storage tank to prevent sudden gas break and protection.

2. The main and auxiliary rotation arms of the power manipulator have the brake function to prevent the accidental rotation and collision of the auxiliary arms and fixtures.

3. The suspension lifting cylinder has a mechanical limit mechanism to effectively prevent the mechanical arm from exceeding the lifting range.

4. The fixed flange of the main arm of the glass-assisted manipulator has a rotation angle limit device, and the rotating arm can be formulated according to the actual site

Rotate the angle range.

5. The rotation function of the clamp arm has a rotation angle limit device to prevent damage beyond the angle range

Air route elements.

6. The product suction device has the balance adjustment function to prevent the inconsistent parallelism of the pickup and release points.

7. The fixture of the manipulator adopts suction suction and is controlled by regions to facilitate the removal and release of products.

8. The balance arm is controlled by full gas control mode, which has the characteristics of high safety and stable work efficiency.

Benefits:

Increased efficiency and productivity.

Improved quality and consistency.

Reduced labor costs and downtime.

Enhanced safety and security.

Features:

6-axis design for maximum flexibility.

Payload capacity of up to 20kg.

High accuracy and repeatability.

Multiple end-effector options available.

Easy to install and program.

Company Profile

Dongguan Yisite Mechanical Automation Equipment Co., Ltd. is the professional manufacturer of machinery automatic equipment,integrated research and development,manufacture,sales and service.We are located in Chang’an Town,mainly supply privatization and customized equipment to 3C electric,automobile,costumes,foods,household electrical appliances,hardware and etc industrial,with strong and solid technology to solve the stuck in production,decrease the manufacturing cost and labor resources,raise the enterprise core competitive power.