Products

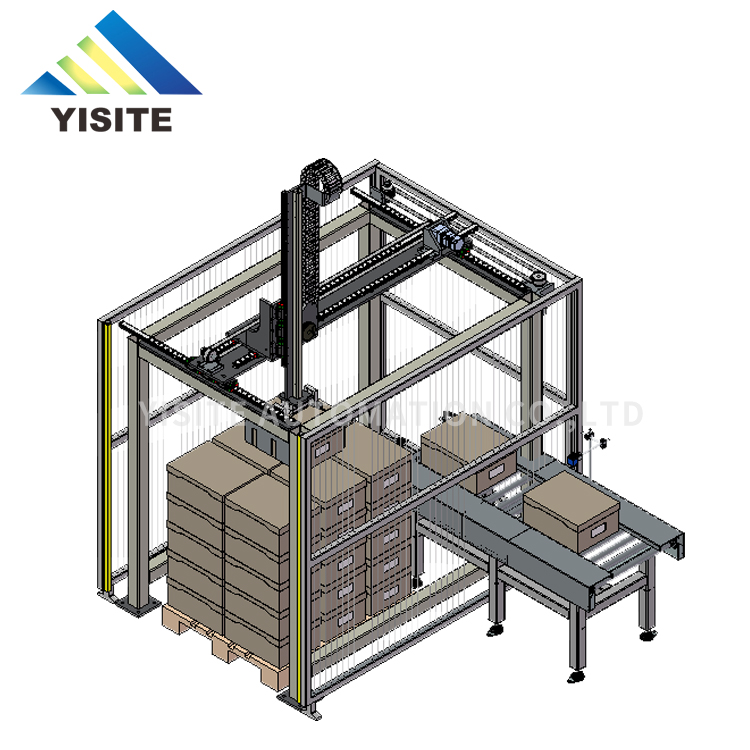

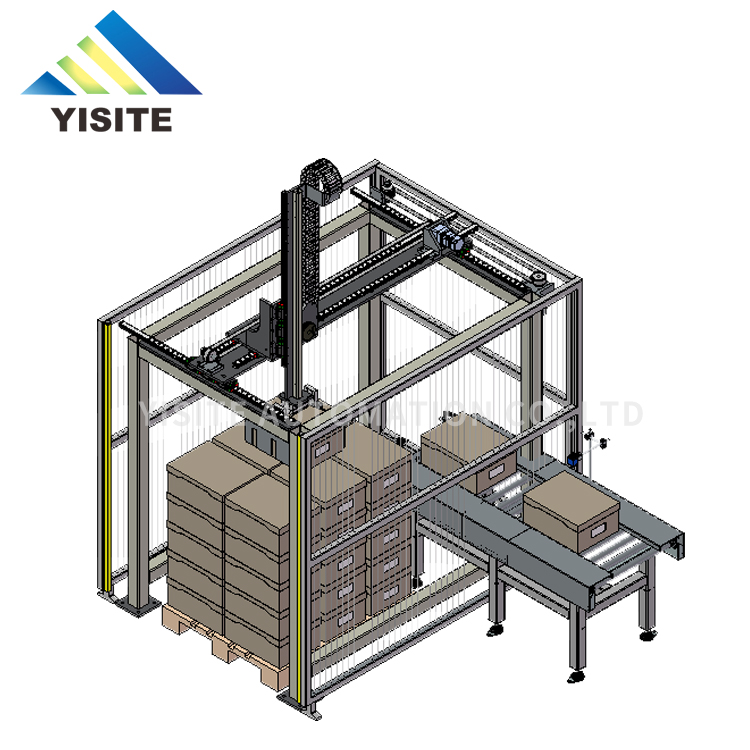

carton box gantry auto palletizer

Truss XYZ fully automatic carton bos stacking manipulator

1. Composition of the stacker machine

The palletizing machine is composed of installation frame, positioning system, servo drive system, control system, electric control and distribution system, safety protection device, etc.,equipped with automatic feed positioning system.(Optional automatic stack supply system)

2. Stacking machine mounting rack

Because the movement speed of the stacker is very fast, the starting state has a great impact on the mounting frame.The installation frame must be very good rigid to ensure the stable operation of the stacking, so we have designed the welded steel frame structure as the support frame.

3. Stacker palletizer machine positioning system

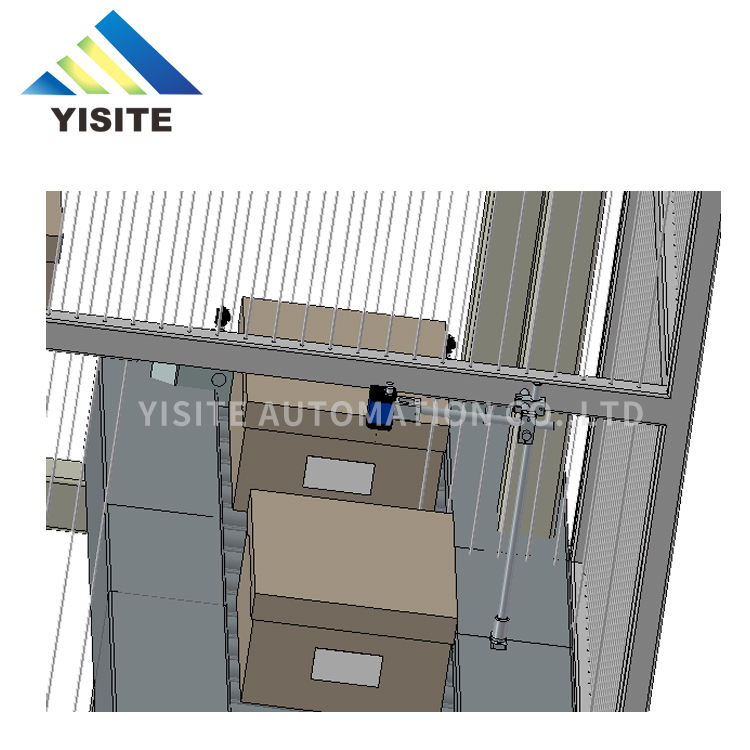

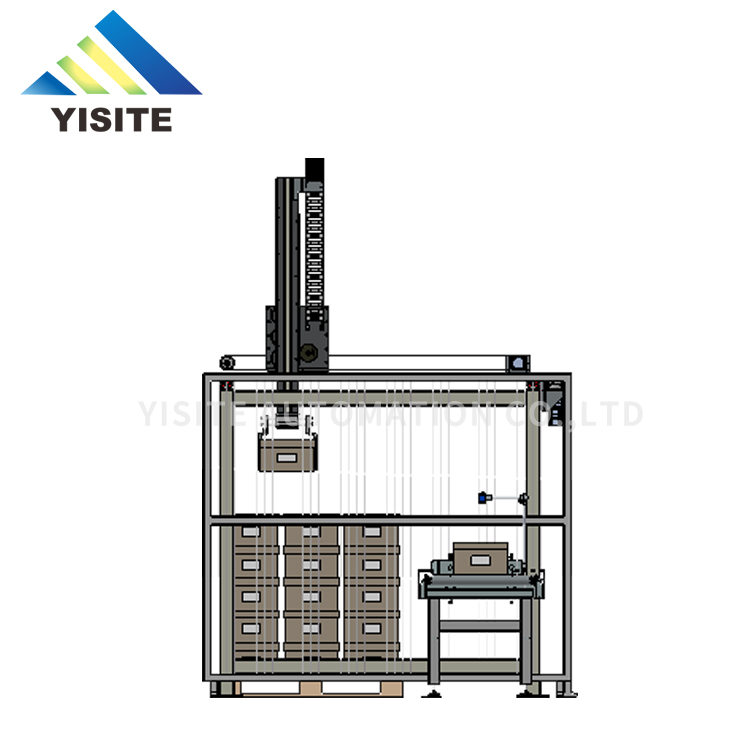

The stacker positioning system is the core of the whole equipment, is the product of Yaskawa Company (Japan), fast motion speed, and the repetition accuracy is high, X, Y, Z three coordinates are selected for synchronous tooth belt transmission, single coordinate repeat positioning accuracy is 0.1mm, fast line motion speed: 1000 mm/s.The X axis is a single positioning system with a single length of 3000mm and a span of 1935mm. The synchronous transmitter ensures the synchronous movement of the two positioning systems and is driven by a 1500W servo motor.For matching the driving torque and inertia, there is a high-precision planetary gear reducer.

The Y-axis using a dual positioning system. The reason why the positioning unit with such a large cross section is mainly because the Y-axis is a double-end support with the middle suspension structure. If the selected cross section is not enough, the stability of the robot movement will not be guaranteed, and the robot will tremble when moving at high speed.Two positioning units are used side by side to clip the Z-axis in the middle and balance the load well. This installation mode has very good stability.The two positioning systems are driven by a 1500W servo motor, equipped with a high-precision planetary gear reducer for matching the drive torque and inertia.

The Z-axis positioning system is firm and stable.The product generally has the slider fixed and the overall up and down movement.The servo motor needs to improve the object quickly, which needs to overcome great gravity and acceleration force, and needs greater power.In practice, we chose a 2000W servo motor, equipped with a high-precision planetary gear reducer.The A axis is the rotation axis.

4. Servo drive system

The stacking manipulator machine using servo motor with digital function.Each motor shaft is equipped with a servo motor and a reducer,four servo motor and four reducer, including vertical motor with lock servo motor.

5. Stacker grip

The stacking with a special design of pneumatic grip, adjustable pressure, equipped with pressure buffer valve, so that the grasp action equipped with induction mechanism, can automatically perceive the object, and inform the control center for the object grasp.

6, control system

The control system consists of a large PLC and a touch screen.The system has powerful programming capabilities.With different models of palletizing,the system can preset a variety of artifact programs, and to replace the corresponding program can be operated on the touch screen.

7, safety device

The machine has a fault prompt and alarm function, and every fault can accurately reflect the specific location, easy and quickly to eliminate faults, mainly including: robot collision protection function; workpiece installation in place detection; light screen safety protection.

Technical parameters

1. Machine model: YST-MD1500

2. Stacking capacity: 200-500 boxes / H

3. Frame : SS41 (A3 steel injection plastic treatment) shaft S45C bearing steel

4. Power: AC, 3 phase, 380V, 9KW 50HZ

5. Air consumption: 500NL / MIN (air use: 5-6kg / cm2)

6. Equipment dimensions: (L) 3500mm (W) 2250mm (H) 2800mm (depends on actual layout design)

7. Equipment weight: 1,500 k g

Main advantage configuration

1. Yaskawa brand servo motor

2. Taiwan brand speed reducer

3. Mitsubishi (Japan) PLC

4. Contactor and switches shall be used in Schneider

5. Omron photoelectric sensor

6. Interface control display action and alarm status and alarm function

7. Yaskawa brand frequency converter

8. The frame and side panels are made by carbon steel

9. Taiwan AirTac Pneumatic elements

10. Italian PIAB brand Sucker