Products

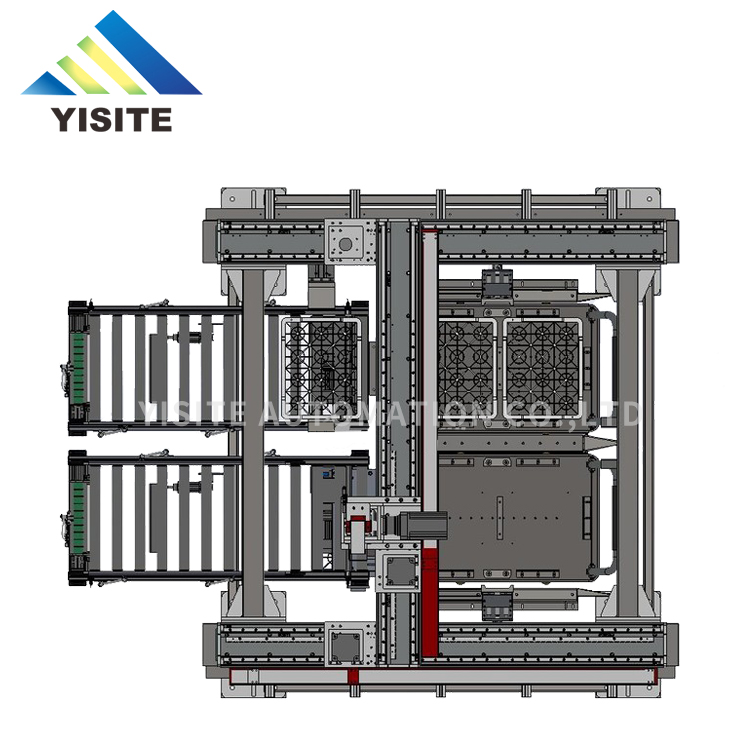

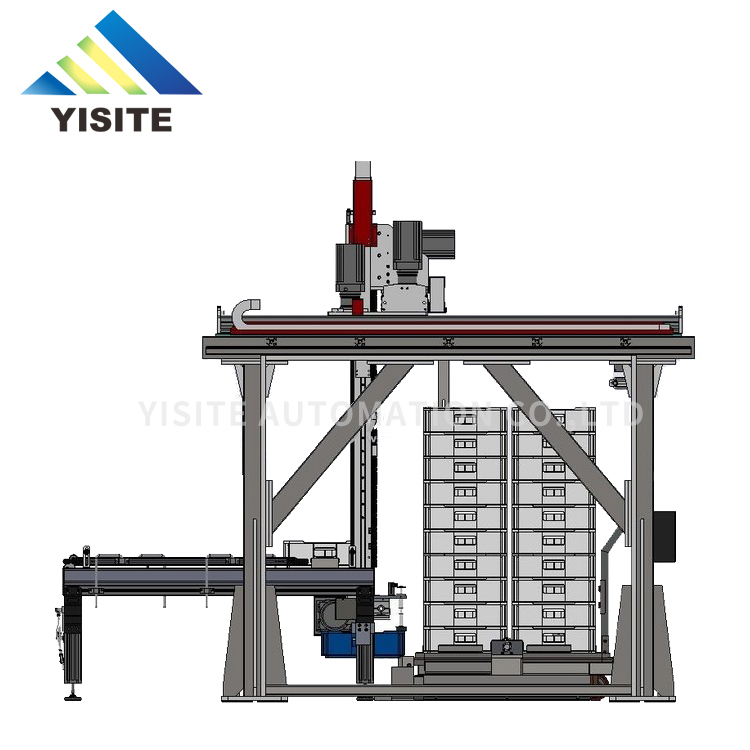

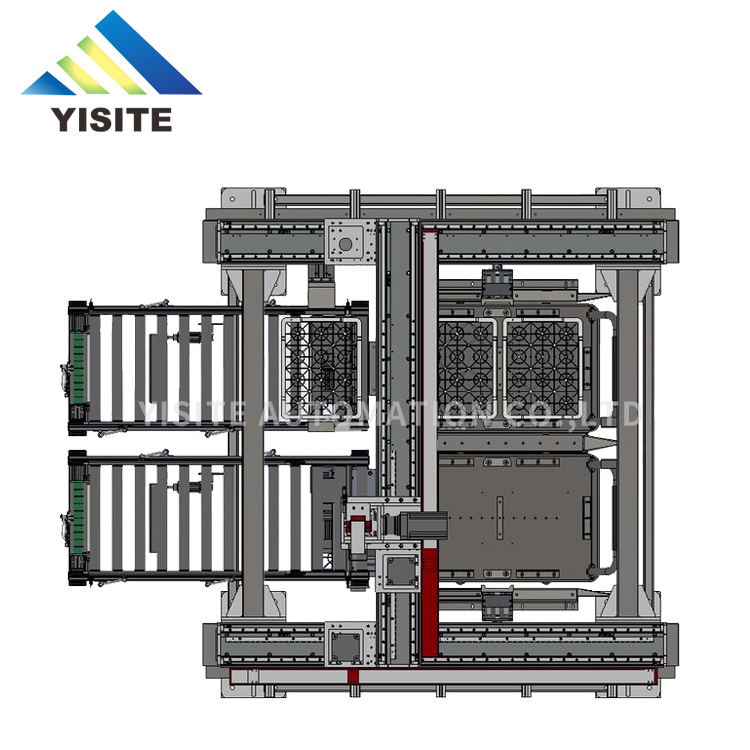

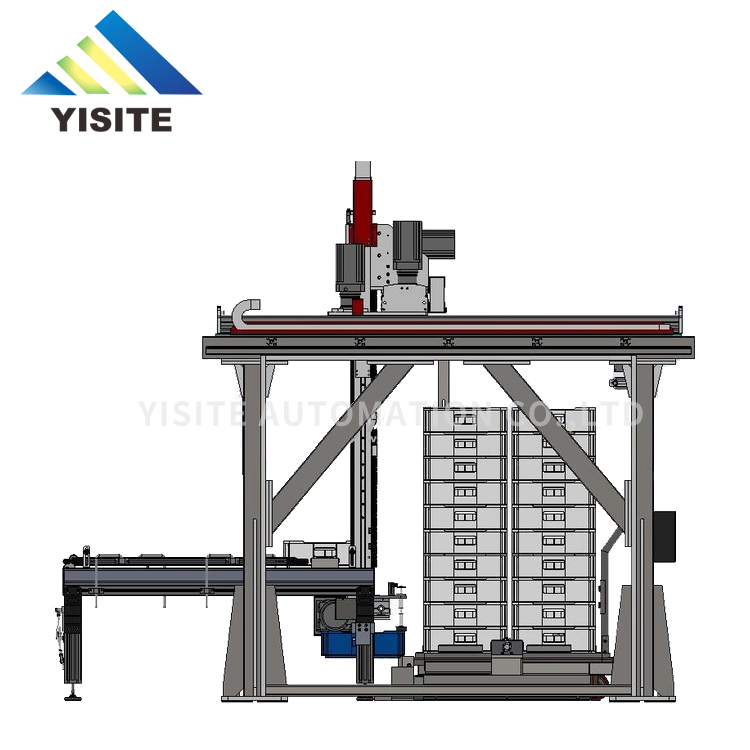

two position gantry robot arm palletizer

Multi line truss fully automatic palletizing manipulator

Double automatic output tray palletizing system, including two delivery lines, palletizing robot,a palletizing robot two production lines.Two palletizing,two production lines,through delivery equipment to double grasp position, according to the line delivery speed, palletizing different materials into the corresponding tray.

The palletizing device fully use the space resources in the factory, based on the existing production line, grasp two bags of materials at the same time, reducing the production costs and labor costs, greatly improves the production efficiency, and fully realizes the unmanned palletizing.

Application of manipulator stacker

Automatic stacker can replace the manual handling of goods stacking,can realize the factory automatic,intelligent,unmanned production.

1. Liberation of labor is the main characteristic of a fully automatic stacking robot machine. A stacker can replace the workload of at least three or four porters, greatly reducing the wage expenditure.The fully automatic stacker has a very low energy consumption.

2. Automatic stacker manipulator robot covers an small area, which is conducive to the placement of production lines in the customer factory, and can leave a large warehouse area.Stacking production line can be set in a narrow space, which can be effectively used.

3. The products of the palletizing machine are neat and standardized, which is more convenient for entry and exit.Automatic stacker has a simple structure and few parts.Therefore, the failure rate of the parts is low, reliable performance, simple maintenance.

4. Using an automatic stacker can effectively improve the production efficiency. Just set up the stacking requirements on the control screen, and it can work continuously day and night.

5. Reduce production cost: The palletizing production line is a fully automated assembly line, which greatly reduces the damage rate of products.

6. Shorten the production cycle: the automatic stacker machine can stack for 800-1000 bags in one hour, several times of artificial. In the case of short production cycle, it can help the company relieve the production pressure.