The power-assisted manipulator is also called a pneumatic balance power-assisted manipulator, a pneumatic balance crane, and a balance booster. It is a novel power-assisted device used for labor-saving operations during material handling and installation. It is a pneumatically assisted, manually operated manipulator. The use of power-assisted manipulators can reduce the labor intensity of operators, achieve light operation and accurate positioning when handling heavy workpieces, and ensure the safety of equipment and operators. The power-assisted manipulator is mainly used to assist workers in handling and assembling, and is a power-assisted handling equipment that reduces labor intensity. It combines ergonomic principles and provides material transportation, workpiece handling and assembly with the concepts of safety, simplicity, efficiency and energy saving. During the transportation process, the equipment is controlled by a logical air circuit, which converts the weight of the heavy object itself into a small manual operating force, easily realizing the movement, transportation and assembly of heavy objects at any position in the operating space, and solving the industrial transportation and assembly problem safely and efficiently. Non-standard customized fixtures can complete actions such as grabbing, transporting, flipping, lifting, and docking workpieces (products), and quickly and accurately assemble heavy objects at preset positions. They are ideal for loading and unloading materials and production assembly. The power-assisted equipment can save labor and improve efficiency for the factory.

The hard-arm power-assisted manipulator consists of a balancing host, a grabbing fixture, and an installation structure. It can balance various weights from 20 to 300kg and is suitable for material transfer operations. The characteristics of full balance and smooth movement allow the operator to easily carry out workpiece handling, positioning, assembly and other operations. It has high stability, simple operation, high efficiency, high safety performance, and is equipped with a gas cutoff protection device. The main components are all made of internationally renowned brands, and the quality is guaranteed. It has a full suspension function and is easy to operate; manufactured according to ergonomic principles, it is comfortable and convenient to operate; the structural design is modular and the air circuit control is integrated; labor costs are reduced by 50%, labor intensity is reduced by 85%, and production efficiency is increased by 50%; according to the load and stroke,they are customized and come in various forms to meet different needs. Scope of application of power-assisted manipulators: widely used in warehouse loading and unloading in the automotive industry, chemical industry, product packaging, electrical appliance industry, ceramic sanitary ware industry, building materials and furniture industry, metal parts, machinery manufacturing and processing, repetitive high-frequency handling work, natural gas and petroleum energy Industry, new energy battery, automated logistics and other industries, equipped with different grippers, it can realize the handling and palletizing of products of various shapes in different industries.

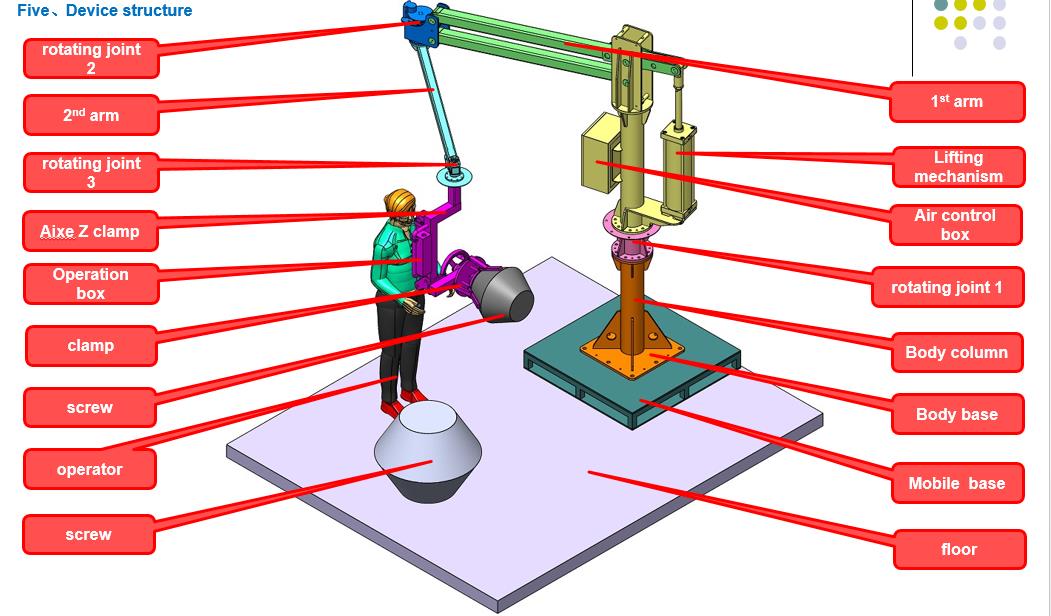

This power-assisted manipulator device consists of a fixed base, body column, joint cantilever, lifting mechanism, Z-axis clamp, operating handle and other mechanical parts. The operator moves the power-assisted manipulator to the graphite electrode. The operator moves the power-assisted manipulator clamp to the ground to grab the graphite electrode screw. After grabbing, it is transported to the graphite electrode thread port, turned over 90 degrees, and the staff tightens the screw threads for assembly. Compared with manual handling, this equipment has lighter operating force, faster operating speed, simple structure, low failure rate, easy maintenance, and low maintenance cost. It applies the force balance principle to allow the operator to push and pull heavy objects. It can move and position balancedly in the corresponding space, especially suitable for handling and palletizing workpieces with precise positioning or assembly requirements. They are used by various industries to reduce operator back injuries and fatigue, while improving production efficiency and quality. Manipulators and accessories are custom designed and manufactured.

The manipulator body is made of carbon steel profiles. The surface is electrostatically powder-sprayed and baked at high temperature. It is more environmentally friendly, beautiful and corrosion-resistant than spray painting. The control system adopts a button mechanical valve + shift switch combination, which is easy to operate and stable in grasping. The contact surface with the product is made of Non-metallic material to protect the product.

The operator uses a forklift to push the power-assisted manipulator to the graphite electrode assembly area for fixation, moves the power-assisted manipulator clamp above the screw on the ground, puts down the clamp, controls the manipulator to clamp the screw through buttons, transports it to the side of the threaded hole of the graphite electrode, flips the clamp, Align the electrode and insert it, then the operator manually rotates the gripper clamp to lock the screw with the graphite electrode. After locking, open the clamp by button to loosen the screw, move the clamp to the ground above the screw again, flip the clamp to pick the screw, and then move to the next graphite electrode to start locking assembly…

Post time: Oct-11-2023