Products

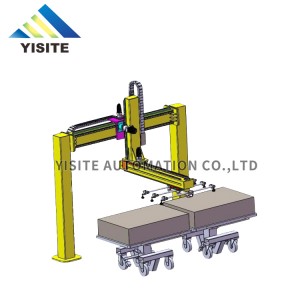

automatic pallet dispenser

Product Details

Pallet dispenser or pallet stacker can be automated for pallet stacking and pallet destacking at floor level with the push of a button from the touch panel. They can detect pallets via photosensors, after which the pallets are stacked or destacked individually by a pallet jack or a forklift. All pallet handling is carried out at the floor level. When selecting to de-stack, a stack of pallets will be inserted in the dispenser, after which the pallets are automatically de-stacked individually. When selecting the stacking mode, the pallets are inserted one by one, after which the pallets are automatically stacked to no more than 15 or 50 pallets depending on the model used. The entire stack can subsequently be removed.

The entire process can be automated to cut costs and speed up your warehouse, picking operation, or facility processes. Each pallet dispenser will improve the overall pallet movement processes and greatly improve employee safety due to reductions in manual pallet handling.

It increases efficiency in the workplace by allowing pallet jacks and other floor-level pallet trucks to retrieve a pallet. Typically used in order-picking applications. Featuring a touch-panel display, automatic and manual mode these are operator friendly and trouble-free.

This pallet stacker improves operational productivity and performance. It provides safe and quick pallet handling for warehouses, distribution centres, factories and companies with high pallet turnovers. The unit creates storage and assists with the organisation of heavy loads, meeting Workplace Health and Safety requirements. Separating forklifts from the order-picking zone is a huge advantage.

Features

Saves on space by organising pallets and ensuring a tidy work area.

Optimize pallet flow and improves the working environment.

Increases efficiency and reduces pallet costs.

Requires no manual pallet handling, therefore reducing hazardous tasks with less absence due to injury or illness.

A leaner machine that reduces time spent per pallet and increases efficiencies with less required resources.

Ensures safety – removing injury risks (like jammed fingers or feet).

Less truck driving.